Flexibility of Outdoor Extension Cords: Flexibility and High-Temperature Resistance

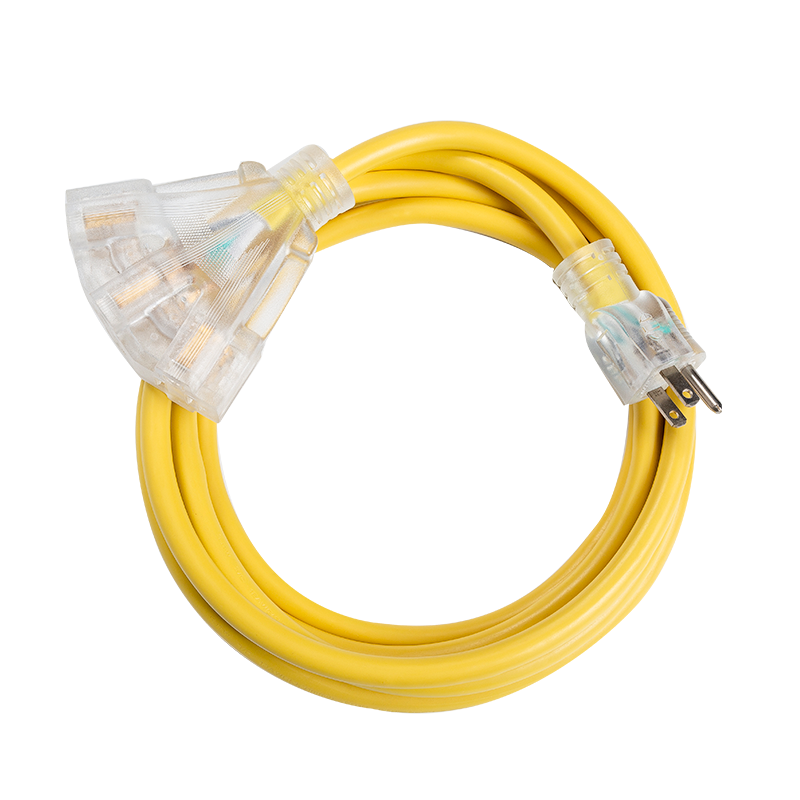

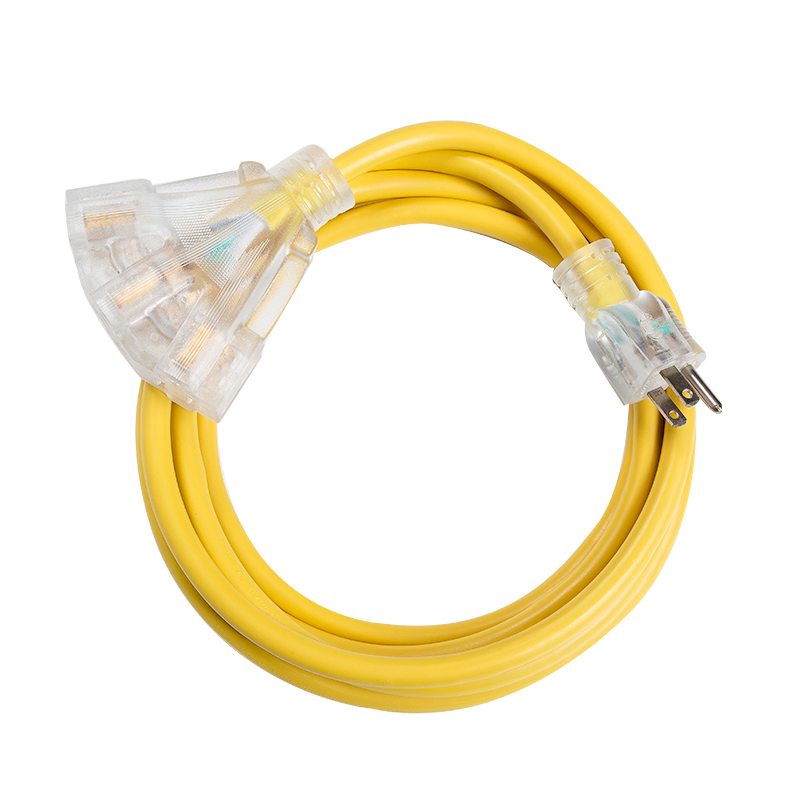

These materials are commonly used for outdoor extension cords due to their superior flexibility. Rubberized and TPE cords remain pliable and easy to handle even in cold temperatures. Rubber's elasticity helps the cord avoid kinking and tangling, making it easier to coil and uncoil. TPE offers similar flexibility with the added benefit of being lightweight and resistant to UV damage.

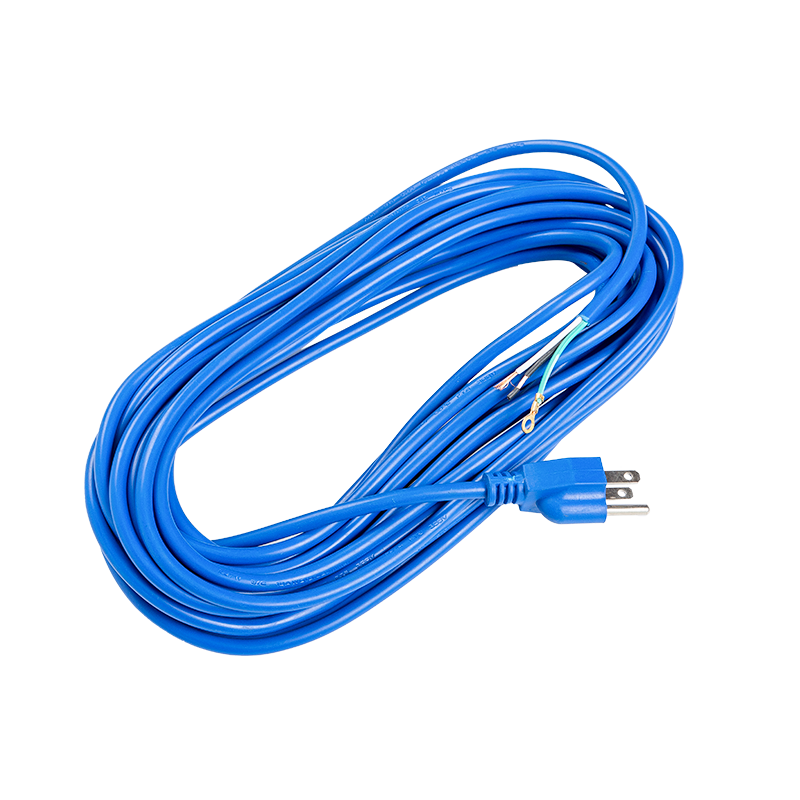

PVC is also used in some outdoor extension cords. While it is generally more affordable, PVC can become stiff in low temperatures, which may affect flexibility. PVC cords are suitable for mild weather conditions but may not perform as well in extreme cold.

High-quality outdoor extension cords designed for cold weather use feature insulation materials that remain flexible in low temperatures. These materials prevent the cord from becoming brittle and difficult to handle. Cords that maintain flexibility in cold weather are essential for ease of use and to prevent damage.

Flexibility is generally less affected by high temperatures. However, cords with high-quality insulation can maintain their flexibility and structural integrity even in warmer climates. Low-quality or poorly insulated cords might become softer but could potentially degrade faster due to prolonged exposure to heat.

Flexible cords are easier to handle, coil, and store without creating kinks. This ease of use is crucial for managing long cords and ensuring they remain in good condition. Flexible cords also tend to have better resistance to mechanical stress, reducing the risk of damage during handling.

Outdoor extension cords with heat-resistant insulation are designed to withstand high temperatures without losing their performance. Materials like rubber and certain TPE formulations are engineered to resist heat and maintain their integrity under thermal stress. These cords can handle temperatures well above typical operating conditions, making them suitable for environments with fluctuating or high temperatures.

While PVC provides some degree of heat resistance, it generally has a lower tolerance for high temperatures compared to rubber or specialized TPE materials. Extended exposure to high temperatures can cause PVC to soften or degrade, potentially affecting the cord's flexibility and safety.

High-quality outdoor extension cords are rated for a specific temperature range. These ratings indicate the temperatures at which the cord can be used safely without compromising its performance. For instance, cords designed for extreme temperatures might have a rating that ensures they remain flexible and functional from as low as -40°F to as high as 140°F (-40°C to 60°C).

Long-Term Exposure: Prolonged exposure to high temperatures can affect any cord’s flexibility and durability. Cords with enhanced insulation and construction are designed to resist heat-induced degradation, maintaining flexibility and performance over time.

Frequent temperature fluctuations can stress the cord’s insulation, causing it to become brittle or lose its flexibility. High-quality cords are engineered to handle thermal cycling better, ensuring they perform reliably even when exposed to varying temperatures.

The flexibility of outdoor extension cords is significantly influenced by the materials used in their construction. Rubber and TPE materials offer excellent flexibility across a range of temperatures, while PVC may become less flexible in extreme cold. For high-temperature resistance, outdoor extension cords with heat-resistant insulation maintain their structural integrity and flexibility even under elevated temperatures. Cords with appropriate temperature ratings and high-quality insulation are essential for ensuring reliable performance and longevity in varying environmental conditions. Proper handling, storage, and selection of the right cord based on temperature and flexibility requirements are crucial for optimal performance and safety.

English

English русский

русский