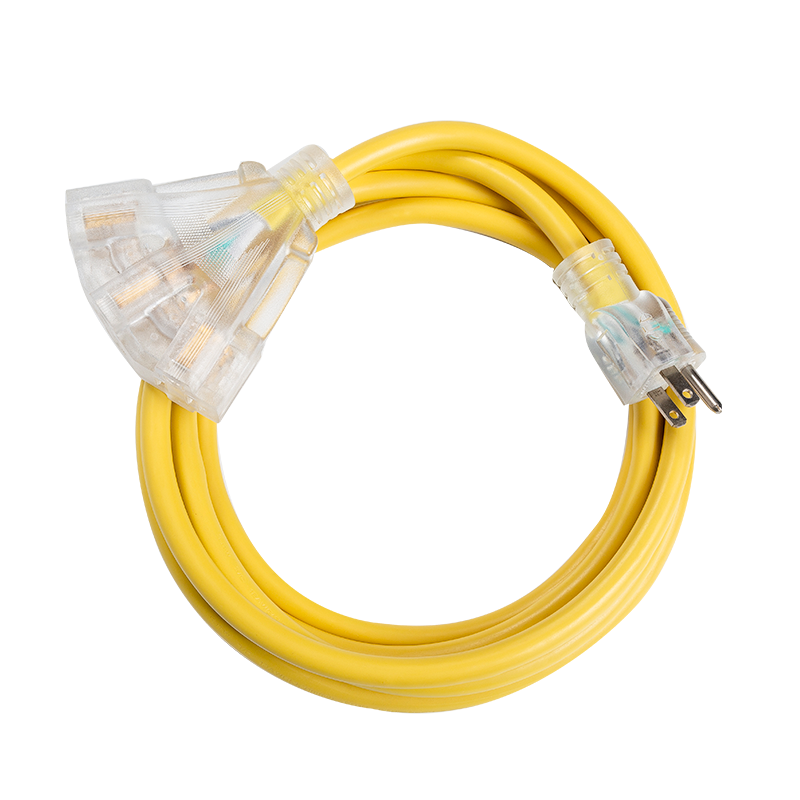

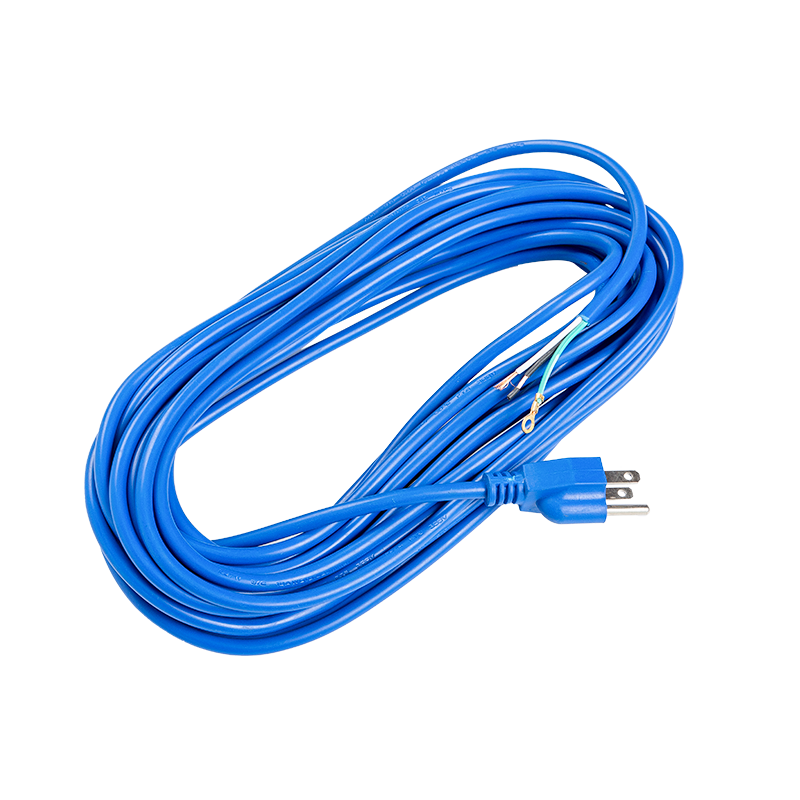

In high current environments, Power Connection Cable needs to ensure safety and prevent overheating, overload, short circuit or other potential electrical failures. To ensure safety in high current environments, cable design and material selection are crucial. Here are some key design and technical measures:

1. Choose appropriate conductor materials

High conductivity materials: Select materials with high conductivity (such as copper or aluminum) as conductors. Copper conductors can effectively reduce resistance and heat generation under high currents due to their excellent conductivity, thereby reducing the risk of cable overheating.

Appropriate conductor size: The conductor of the cable needs to be designed according to the expected current load to ensure that the conductor can carry high current without overheating. Too thin conductors may lead to excessive resistance, thereby increasing heat generation and even causing failures.

2. Optimize the insulation layer of the cable

High temperature resistant insulation materials: The insulation material of the cable (such as cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC)) needs to be able to withstand high temperatures to prevent the heat generated when the current passes through from causing the insulation layer to melt or fail.

Thickness control: In order to improve insulation, the thickness of the insulation layer can be appropriately increased to improve the heat resistance and anti-puncture ability of the cable, and ensure that the insulation layer is not damaged under high current conditions.

3. Enhance the heat dissipation capacity of the cable

Excellent thermal conductivity: When designing cables, it is necessary to ensure good thermal conductivity between the conductor and the external environment in order to effectively dissipate heat. By selecting materials with good thermal conductivity and increasing the surface area of the conductor, the cable can be helped to dissipate heat better under high current.

Heat dissipation design: During the design process, you can consider using multiple strands of thin conductors (rather than a single thick conductor). These thin conductors can increase the surface area when the current passes through, thereby effectively improving the heat dissipation capacity.

4. Anti-overload protection

Overload protection devices: Installing overload protectors (such as fuses and circuit breakers) is an effective means to ensure safety in high current environments. These protection devices can cut off the power supply when the current exceeds the predetermined safety value to prevent the cable from being damaged or causing a fire due to overload.

Overload detection: By installing overload detection sensors in the cable system, the current changes are monitored and the protection mechanism is automatically activated in the event of an overload.

5. Heat and fatigue resistance of cables

High temperature resistant materials: High current transmission will cause a lot of heat to be generated in the cable. Therefore, using high temperature resistant materials (such as cross-linked polyethylene XLPE, fluoroplastics, etc.) as insulation and sheath materials can effectively prevent overheating and material aging.

Anti-fatigue design: Cables will experience continuous mechanical stress such as stretching and bending during long-term use. Increasing the fatigue resistance and tensile resistance of cables can avoid electrical failures caused by mechanical damage.

6. Use high-strength outer sheath

Protective effect of outer sheath: The outer sheath of the cable (such as PVC, polyurethane, etc.) not only plays a physical protection role in high current environments, but also provides additional thermal protection to prevent the cable from being damaged by high temperature or mechanical impact in the external environment.

Wear and impact resistant design: In high current environments, cables may be subjected to large external force impact or friction. Therefore, the outer sheath of the cable needs to have high wear and impact resistance to prevent external physical damage from causing electrical failures.

7. Cable shielding design

Electromagnetic shielding: In a high current environment, changes in current may generate electromagnetic interference (EMI), affecting the normal operation of other devices. By adding a metal shielding layer or a copper braided mesh to the cable, electromagnetic interference can be effectively reduced and the equipment can be protected from interference caused by high current.

Reducing electromagnetic radiation: By adopting an aluminum foil shielding or copper foil shielding design, electromagnetic radiation and electrical interference can be further reduced to ensure stable and safe power connections.

Through precise material selection, structural design and protection measures, the stability and safety of the cable in a high current environment can be effectively guaranteed, the risk of failure and fire can be reduced, and the safe and reliable operation of the power system can be ensured.

English

English русский

русский